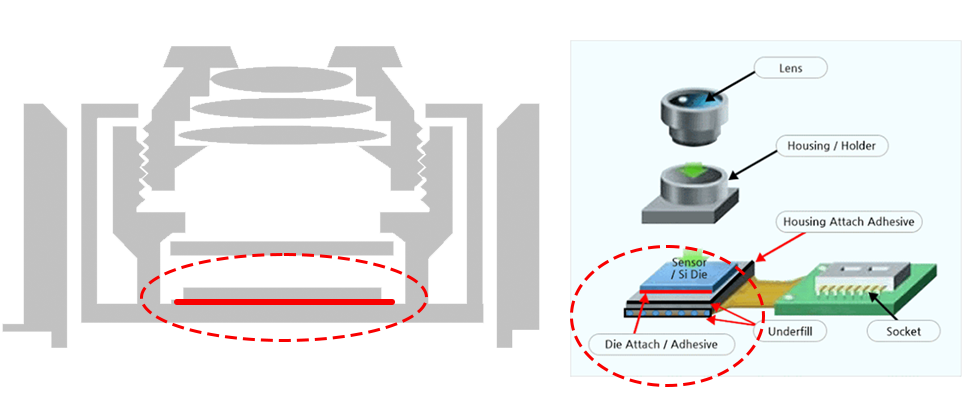

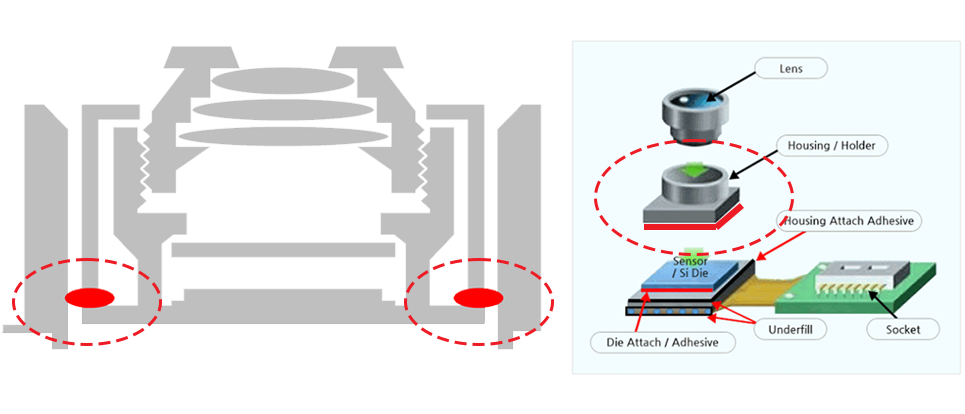

Adhesives for Camera Module Assembly

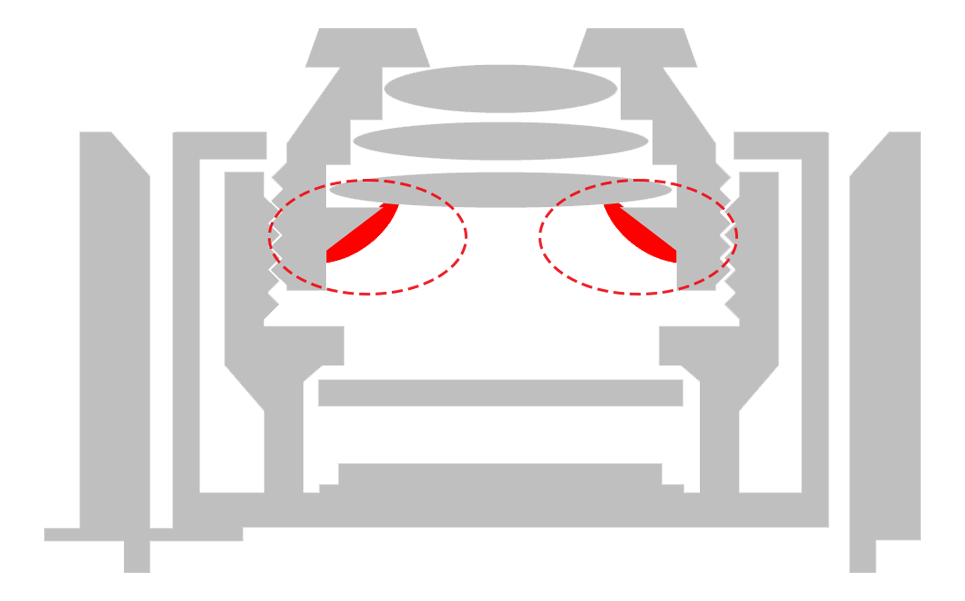

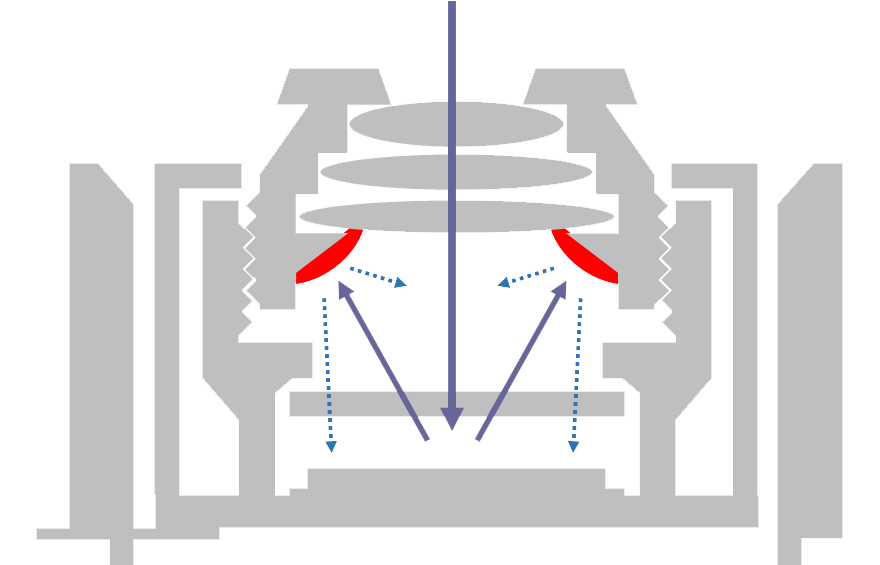

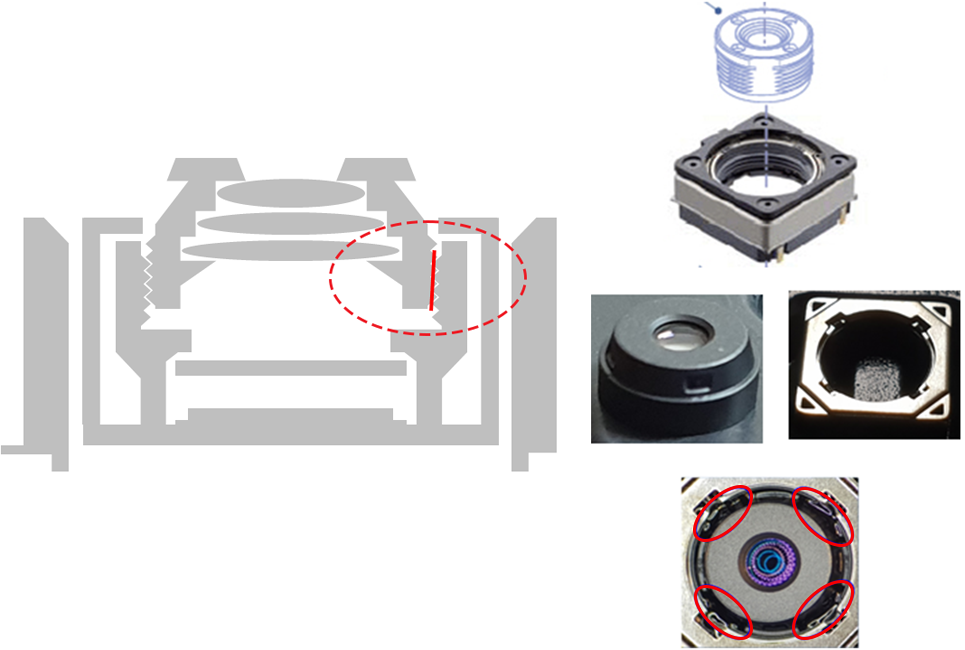

1. Lens fixing

- UV or UV+Heating Curing

- Good adhesion

- Low transmittance

- Low reflectivity

- No flare

- Good curing depth

- High thixotropy

2. Flange fixing

- UV Curing

- Good adhesion

- Excellent curing depth

- Good workability

- Excellent reliability

2. Flange fixing

- UV Curing

- Good adhesion

- Excellent curing depth

- Good workability

- Excellent reliability

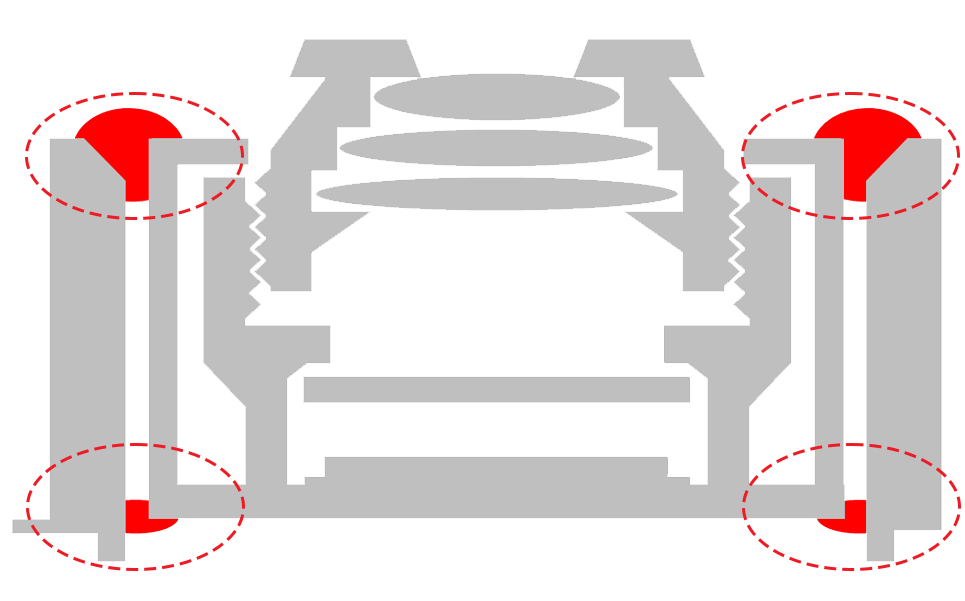

3. Barrel fixing

- Good adhesion

- Low shrinkage

- Dual cure (UV+heat)

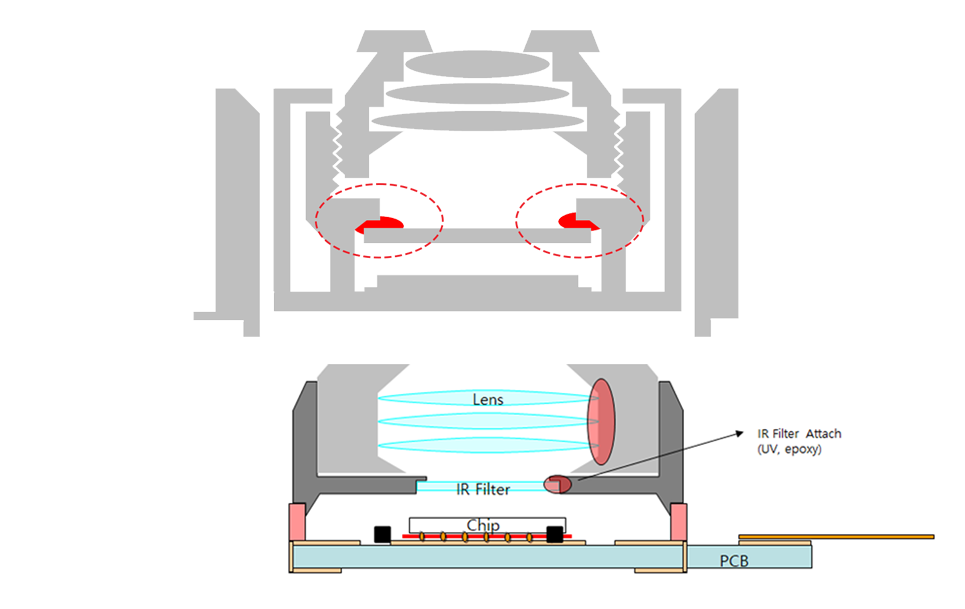

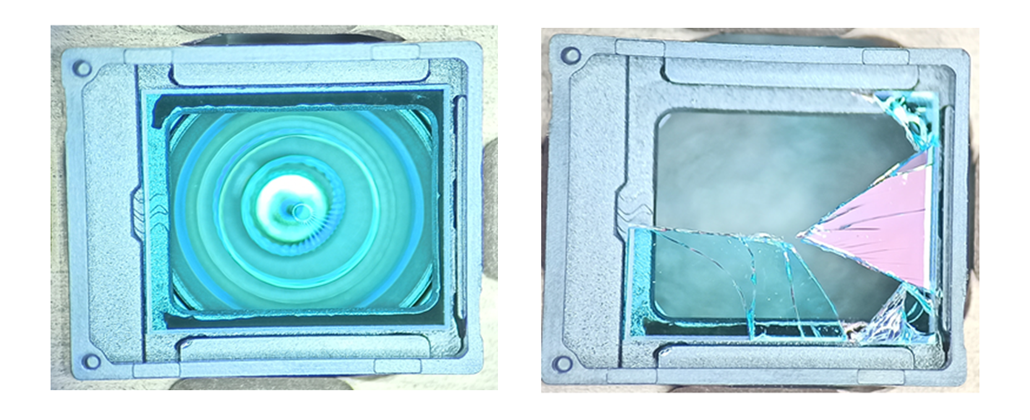

4. IR Filter Bonding

- Good adhesion

- Low RBO

- Low temp cure

5. Die attach

- Low temp cure

- Low warpage

- Fast cure

6. Housing attach

- High adhesion to LCP, PA

- Low temp cure

- Fast cure

- Dual cure (UV+heat)

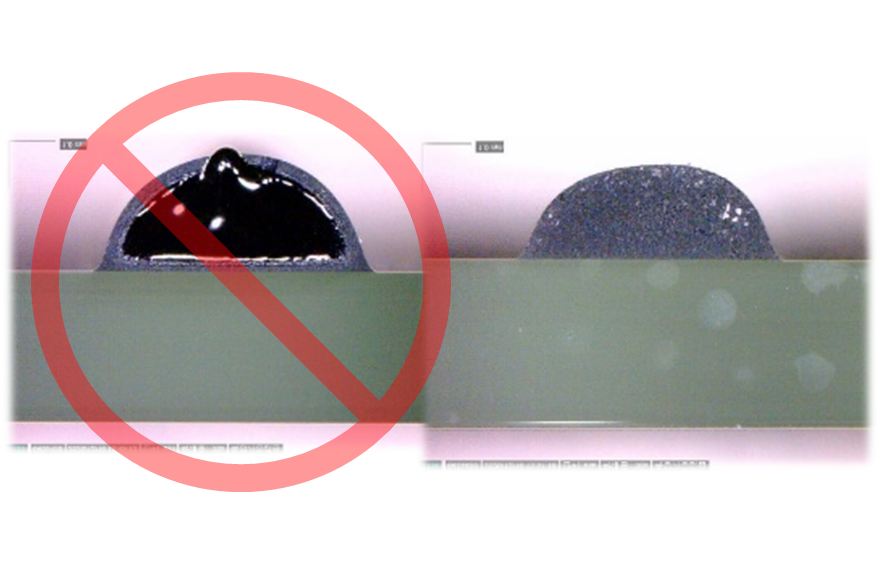

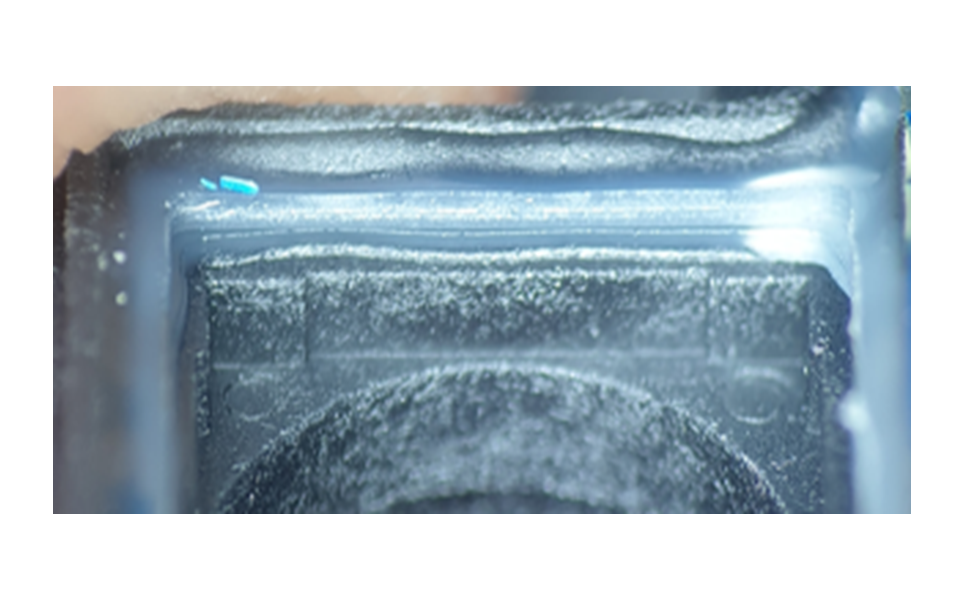

1. Lens fixing

What is lens fixing resin?

UV hardened resin for lens and barrel bonding.

Product characteristics

Good adhesion

Excellent disassembling force Reliability improvement

No Flare

Low reflectivity and low transmittance Improve the Flare phenomenon caused by light reflection

Good curing depth

Deep hardening is excellent Improve the speed of work Improve the rate of Defective rate

High thixotropy

Excellent thixotropy Improvement Gate(hole)blockage

Physical properties

| Product Name | Curing Condition | Viscosity [cP] | Thixotropic Index | Hardness [D type] |

|---|---|---|---|---|

| UC-1003B Series | 2,000mJ/cm2 | 2,000 ~ 20,000 | 2.0 ~ 6.0 | 30 ~ 80 |

| TB-1QUS-RE(V4) | 2,000mJ/cm2, 80℃ / 30min | 10,000 ~ 15,000 | 2.0 ~ 4.0 | 50 ~ 70 |

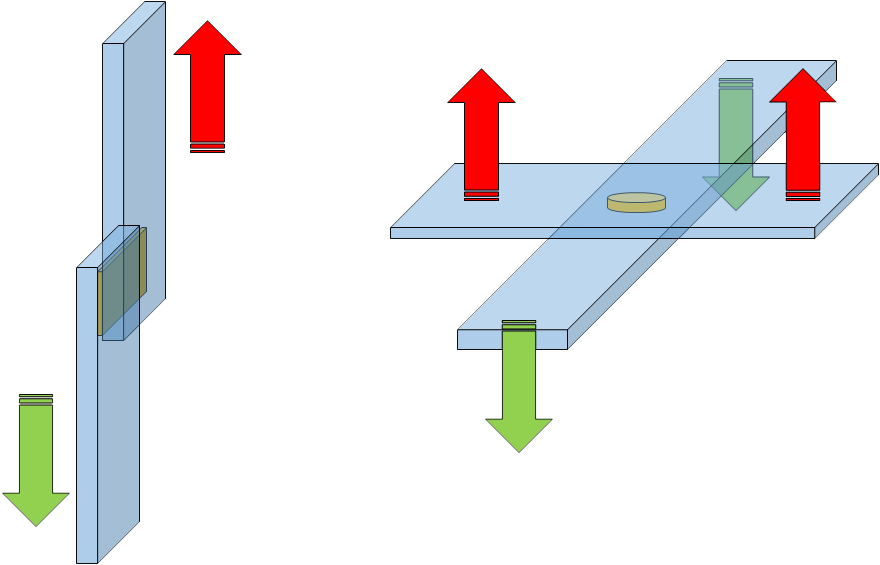

2. Flange fixing

What is Flange Fixing Resin?

UV hardened Resin. for VCM and Flange bonding.

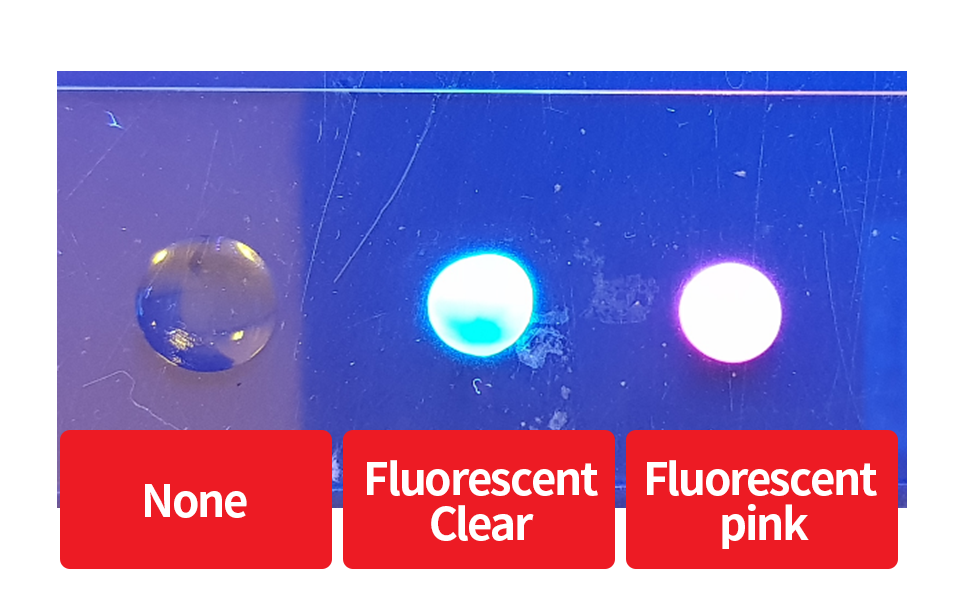

Product characteristics

Good adhesion

Excellent disassembling force Reliability improvement

Vision inspection

Fluorescent substances can be used for visual inspection Improve the rate of Defective rate

High thixotropy

Excellent thixotropy Can also be stably coated on the wide model between VCM and Flange

Good curing depth

Deep hardening is excellent Improve the speed of work Improve the rate of Defective rate

Physical properties

| Product Name | Curing Condition | Viscosity [cP] | Thixotropic Index | Hardness [D type] |

|---|---|---|---|---|

| UC-133B Series | 2,000mJ/cm2 | 2,000 ~ 8,000 | 1.5 ~ 2.5 | 50 ~ 60 |

| UC-1355 Series | 2,000mJ/cm2 | 3,000 ~ 8,000 | 2.0 ~ 5.0 | 40 ~ 80 |

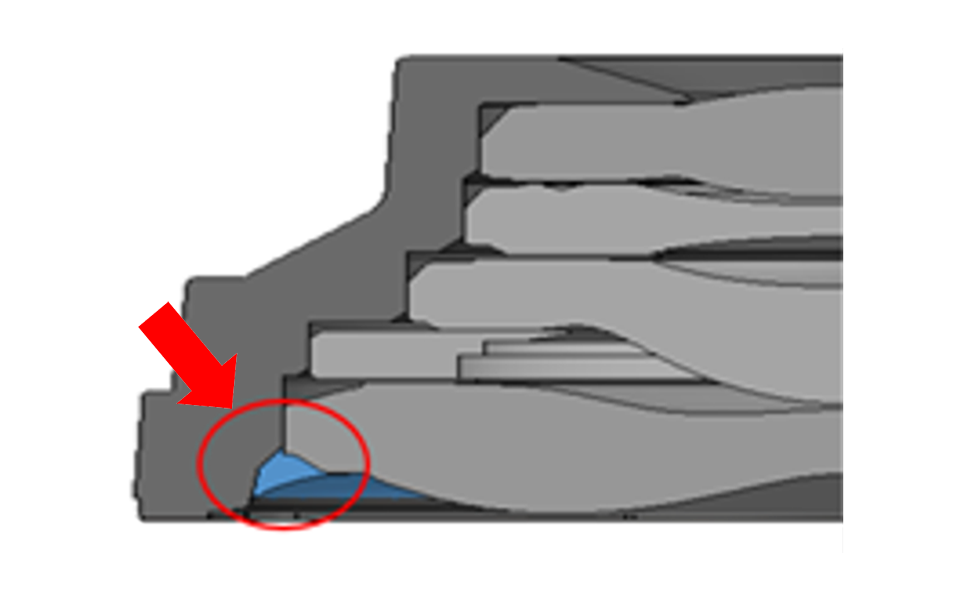

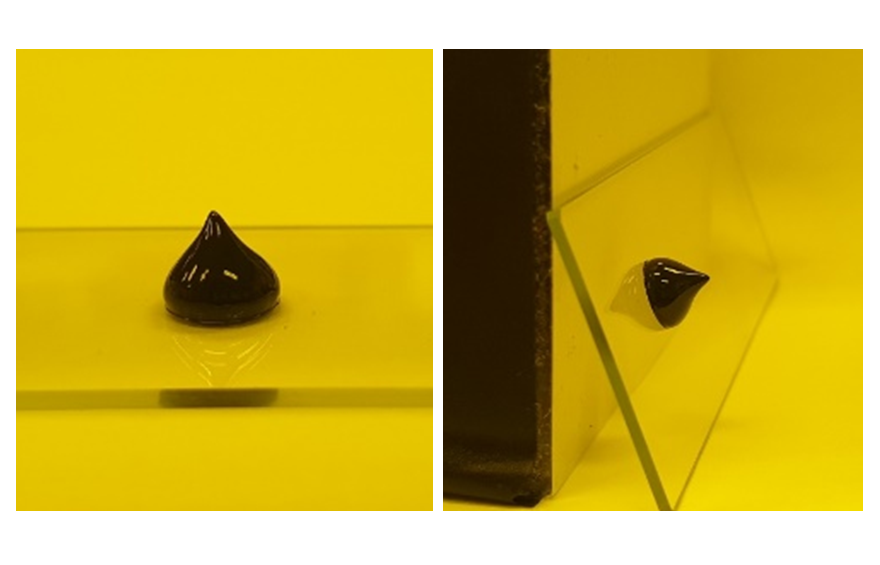

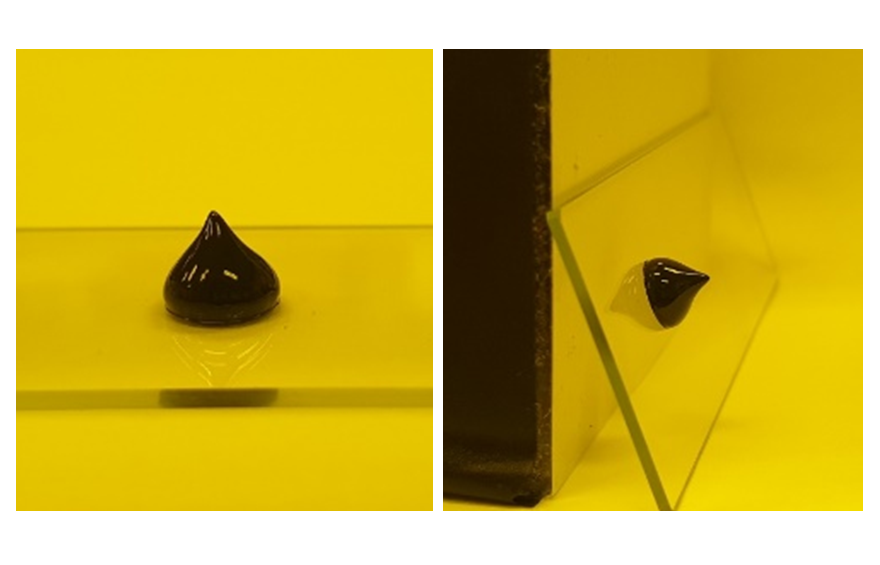

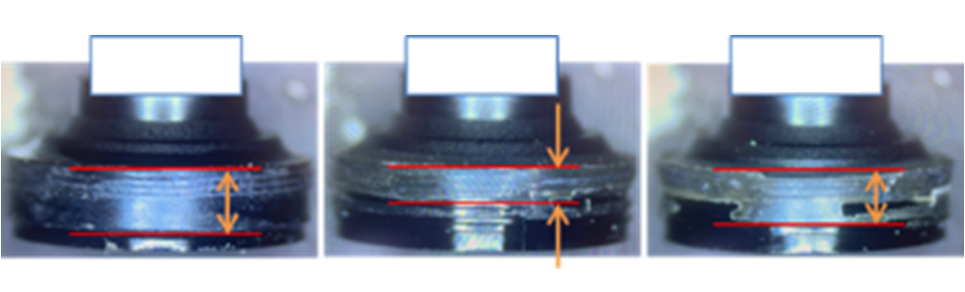

3. Barrel fixing

Barrel

Thermosetting Resin used in coating and curing process for barrel and retainer permanent assembly.

Product characteristics

- - Most suitable viscosity / thixotropy

- - A certain degree of penetration

- - Excellent adhesion force above 45 kgf after curing

- - Dual cure: after UV pre hardening, the change rate of thermal hardening is less than 0.22%

Physical properties

| SAC-9663 | TB-1QUS-LB | ||

|---|---|---|---|

| Main component | Epoxy Only heat | Epoxy + Acrylate UV+ Heat system |

|

| Appearance | Black | Dark gray | |

| Curing condition | Heat | 80℃ x 20min | 80℃ x 30min |

| UV [mJ/cm2] | 2,000 | ||

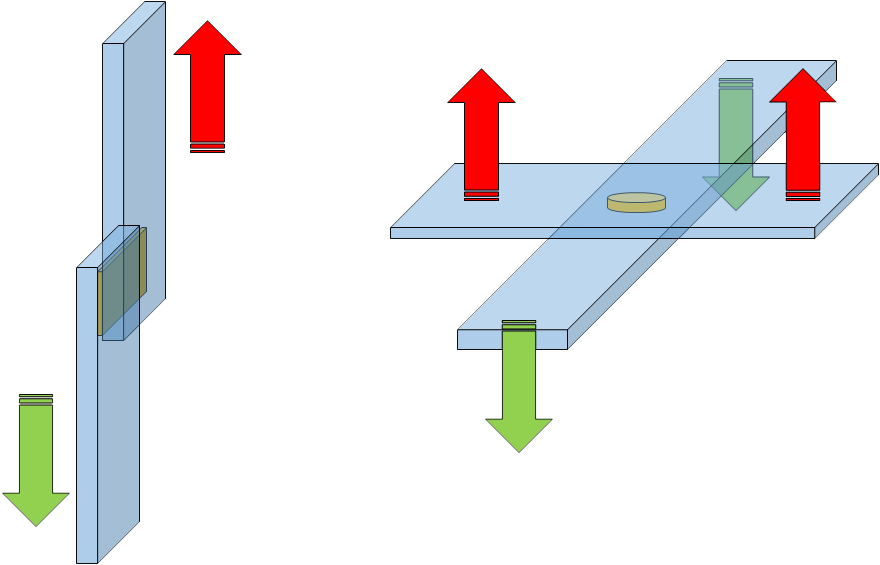

4. IR Filter Bonding

IR Filter attach

The thermal hardening Resin, binds the IR filter and the Holder together, which are components of a digital imaging device that can be achieved by blocking infrared and Transmits visible light.

Product characteristics

- - Viscosity and thixotropy suitable for 4 point dotting process

- - Low viscosity type, excellent dotting spreadability

- - Excellent adhesion to Film filter or glass filter

- - Low Reins Bleed Out

- - It can cure rapidly at low temperature

Application example

- - SAC-9640 : Suitable for low-pixel 5M products

- - SAC-9640-15 : Suitable for high-resolution 48M or 68M

Physical properties

| SAC-9640 | SAC-9640-15 | UC-199F | |

|---|---|---|---|

| Main component | Epoxy Only heat | Epoxy Only heat | Urethane Acrylate |

| Appearance | Black | Black | Light yellow |

| Curing condition | 80℃ x 30min | 80℃ x 20min | 2,000mJ/cm2 |

5. Die attach

Die attach

A thermosetting resin that recognizes the pattern of a specific position on the PCB substrate through an image, attaches the image sensor to a certain position and hardens it.

Product characteristics

- - Viscosity and thixotropy suitable for process : Excellent Tilt

- - Dispensing process operation performance is good

- - Low warpage

- - Excellent adhesion to metals, forming a soft or hard type product group

- - It can be cured rapidly at 80℃ or 120℃.

Application example

- - SDA-9000 : Suitable for Models requiring low hardness, low modulus and fast curing at 80℃ x 2min

- - SDA-9505 : Suitable for models requiring very high adhesion and curing at 120℃ x 2min

Physical properties

| SDA-9000 | SDA-9505 | |

|---|---|---|

| Main component | Epoxy Only heat | Epoxy Only heat |

| Appearance | Black / Ivory | Black / Red |

| Curing condition | 80℃ x 2min | 120℃ x 2min |

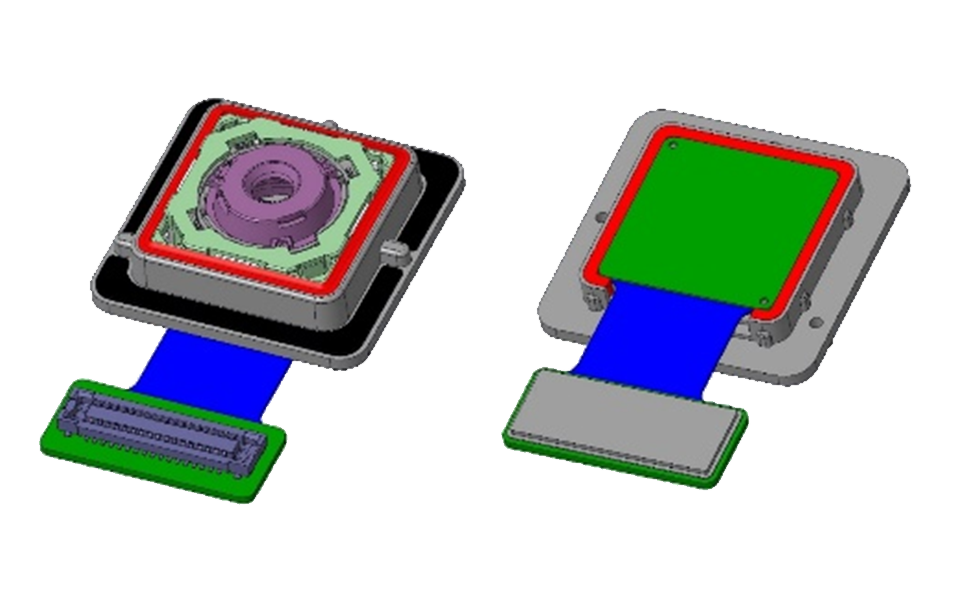

6. Housing attach

Housing attach

In order to paste the Housing module equipped with RENS on the edge of the substrate where the image sensor is mounted, heat or UV+ thermosetting resin is used.

Product characteristics

- - Good Dispensing operation

- - Viscosity / thixotropy has a variety of products, can be applied according to process speed

- - Good adhesion to LCP / PPA materials

- - After drop test and reliability, the adhesion force decreases little

- - It can cure rapidly at low temperature

Application example

- - SAC-9626 / SAC-9836 : Low hardness, Low modulus characteristics, Especially suitable for models with impact resistance requirements

- - TB-1QUS-C11 : double cure, has good adhesion

Physical properties

| SAC-9626 | SAC-9836 | SAC-9826 | TB-1QUS-C11 | ||

|---|---|---|---|---|---|

| Main component | Epoxy Only heat | Epoxy Only heat | Epoxy Only heat | UV+ Heat system | |

| Appearance | Black | Black | Black | Dark gray | |

| Curing condition | Heat | 80℃ x 30min @ dry oven |

80℃ x 30min @ dry oven |

80℃ x 30min @ dry oven |

80℃ x 30min |

| 90℃ x 3min @ hot-plate |

90℃ x 3min @ hot-plate |

90℃ x 3min @ hot-plate |

|||

| UV [mJ/cm2] | 2,000 | ||||